Now, let us take you through the nine key steps from inspiration to finished product, where every stage is carefully crafted to present jewelry in its utmost perfection.

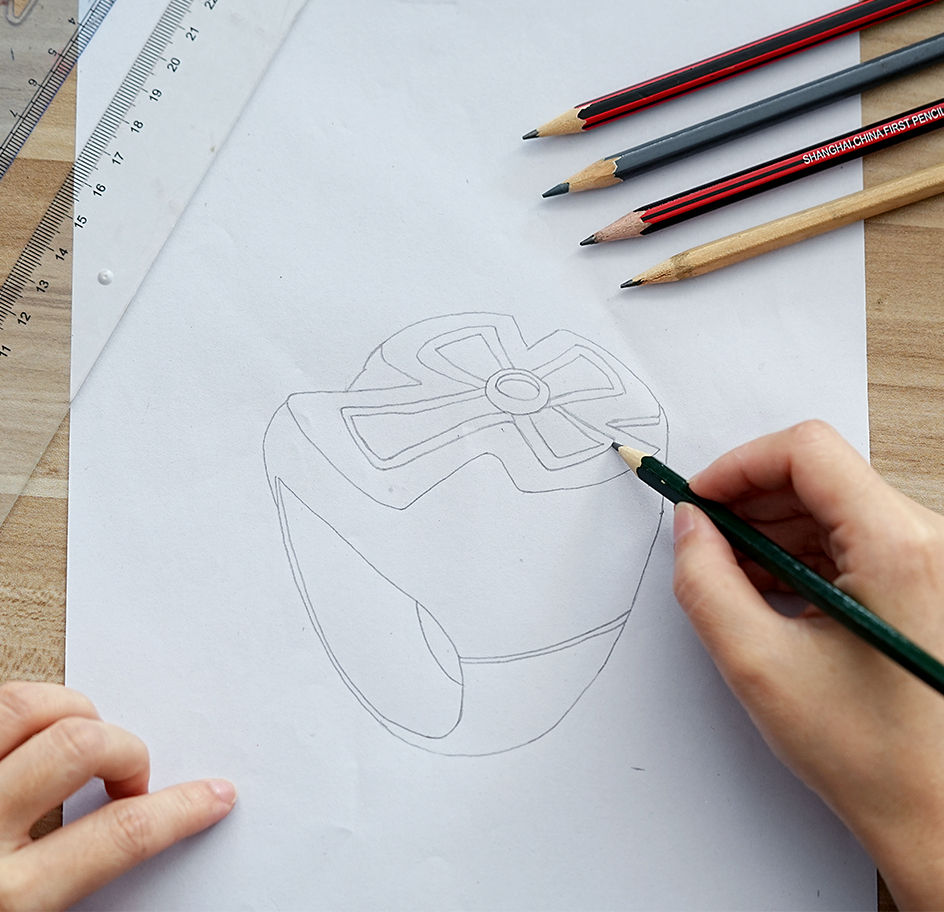

During this stage, we delve into the functionality, artistry, and market demand of the jewelry. Through careful adjustments and feedback, we finalize the design concept, ensuring that each piece of jewelry perfectly integrates creativity and practicality.

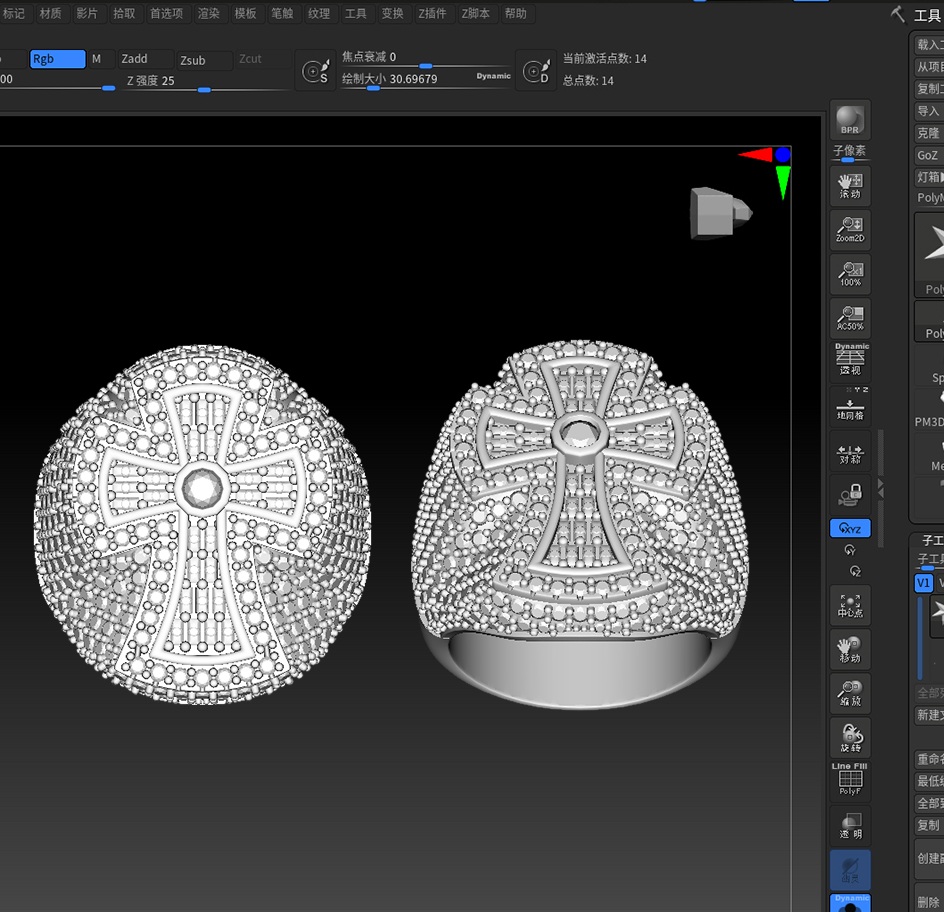

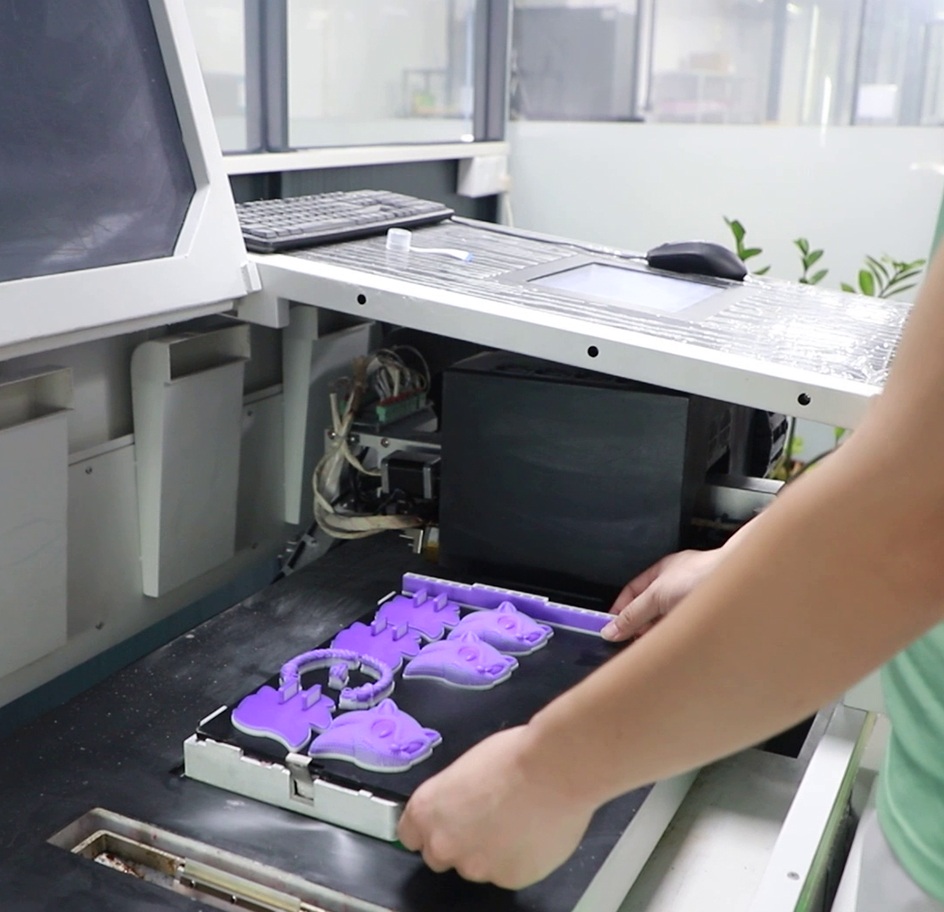

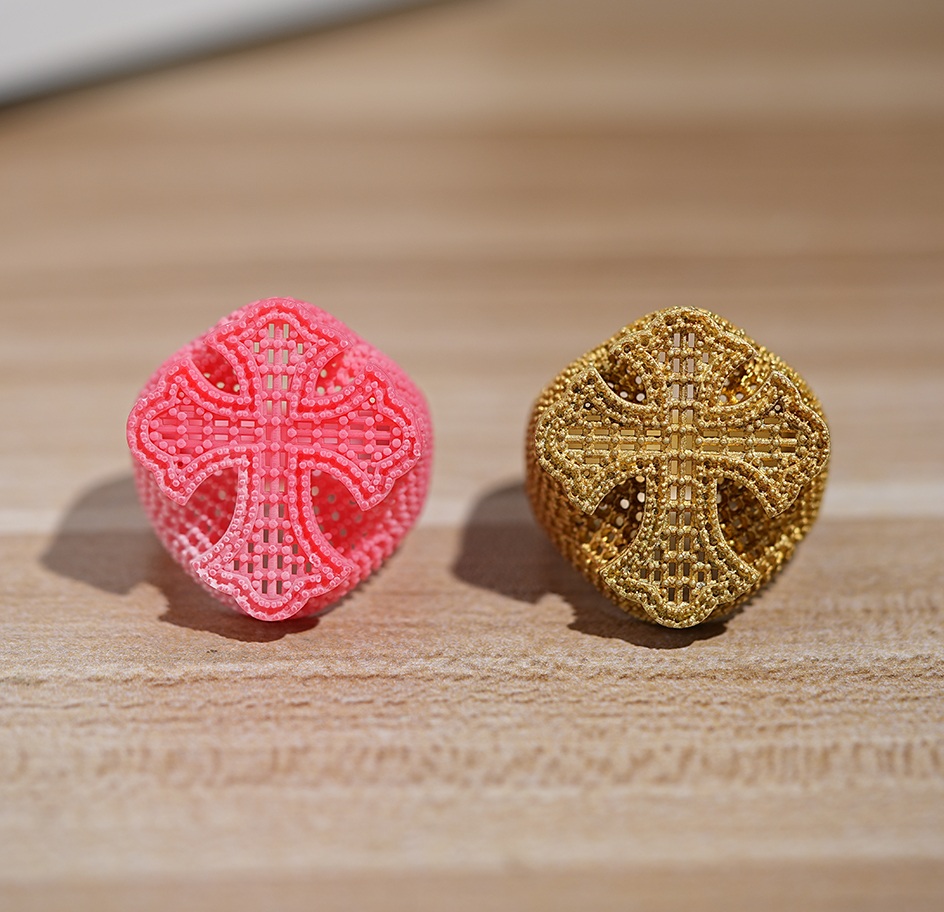

This is a crucial step that ensures the smooth transition of the 3D model from a digital concept to a physical form, laying the foundation for the precision and intricate details of the design product. It serves as the cornerstone of high-quality jewelry production.

Next, we enter the mold and sample production stage. Our professional production team, with their exceptional jewelry-making expertise, precisely transforms the wax mold into a metal prototype. The entire casting process requires high precision and meticulous operation to ensure the perfect formation of each piece of jewelry.

Hand Setting: Focused on achieving exceptional quality, this method is ideal for classic pieces with a prominent center stone and high-end custom designs, ensuring each gemstone is securely set and every detail is flawlessly displayed.

Wax Setting: Efficient and precise, this method is suitable for mass production of pavé-set small gemstones, effectively controlling costs while ensuring overall aesthetic appeal.

Whether it’s the traditional hand setting or the modern wax setting technique, Shining Star Jewelry approaches each gemstone with craftsmanship, ensuring that every gemstone radiates its most captivating brilliance.

Shining Star Jewelry offers a variety of plating options to meet your needs for different plating colors. Our plating thickness exceeds industry standards, ensuring a longer-lasting color retention. Additionally, we provide plating thickness inspection reports for each batch of products, ensuring strict quality control. Furthermore, we offer Gold Vermeil plating, further enhancing the jewelry’s luster and durability.

We are dedicated to ensuring that each piece of jewelry displays perfect gloss and a long-lasting, like-new surface texture, providing you with an unparalleled jewelry experience.

Shining Star Jewelry adheres to the quality philosophy of "pursuing excellence" and has established a comprehensive jewelry quality assurance system throughout the entire process, ensuring that each piece can withstand the test of time.

Strict Confidentiality Mechanism

Strict Confidentiality MechanismWe sign legally binding Non-Disclosure Agreements (NDAs) to fully protect the confidentiality of our clients' products and privacy. From drawings to finished products, we implement encrypted management throughout the process to ensure zero risk of leakage.

Ensuring Consistent Quality Between Samples and Mass Production Orders

Ensuring Consistent Quality Between Samples and Mass Production OrdersWe have established a strict quality control system and commit to ensuring that the mass-produced jewelry matches the sample exactly. After the sample is completed, we establish a standardized production process to ensure high consistency in raw materials, craftsmanship, equipment, and inspection procedures. At the same time, we use the sample as the standard and conduct strict referencing, ensuring that each product undergoes meticulous checks and strict control at every production stage, maintaining superior craftsmanship and perfect details.

Fast Sample Delivery

Fast Sample DeliveryWe are dedicated to accelerating the sample production process and providing fast sample delivery services. Once the sample is completed, we immediately arrange express shipping to ensure it reaches the client safely and quickly within 2-3 days, helping clients to evaluate and confirm in a timely manner, effectively shortening the product development cycle by over 40%.