Hip-Hop Jewelry Brand ODM/OEM Comprehensive Solutions

Shining Star Jewelry's Excellence in Manufacturing

Shining Star Jewelry is a seasoned jewelry manufacturer with 15 years of industry experience. The company is equipped with an 1850㎡ modern production facility and over 70 advanced international production machines, along with more than 200 skilled workers. We have built a complete production line with the capacity to produce over 50,000 pieces of hip-hop jewelry per month.

With our fully integrated production line and one-stop service, ranging from Jewelry design, production, to logistics and distribution, we guarantee:

✓ 500,000 pieces annual production capacity

✓ 99.5% on-time delivery rate

✓ 99.9% product qualification rate

With our fully integrated production line and one-stop service, ranging from Jewelry design, production, to logistics and distribution, we guarantee:

✓ 500,000 pieces annual production capacity

✓ 99.5% on-time delivery rate

✓ 99.9% product qualification rate

0㎡

0㎡ 0team members

0team members 0PCS

0PCS

Elite Manufacturing Team, Quality Assurance

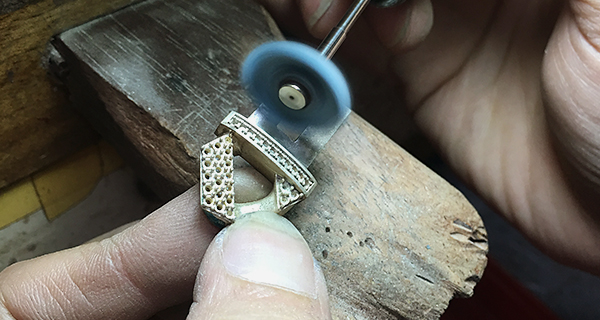

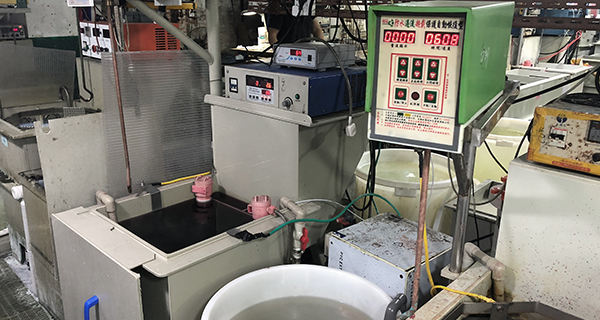

The Production Process of Shining Star Jewelry

Fully self-managed production process, with samples delivered in 1-2 weeks and bulk orders completed in 2-4 weeks, ensuring delivery times are 30% faster than the industry standard.

Production Advantages:

Production Advantages: Fully Controllable ProcessAll steps are completed in our own factory, with strict control over every production stage to avoid quality fluctuations and delivery delays caused by outsourcing.

Fully Controllable ProcessAll steps are completed in our own factory, with strict control over every production stage to avoid quality fluctuations and delivery delays caused by outsourcing. Flexible ResponseProduction processes and rhythms can be adjusted according to customer needs, offering customized production solutions.

Flexible ResponseProduction processes and rhythms can be adjusted according to customer needs, offering customized production solutions.

| Stable Quality | Fast Delivery | Customized Craftsmanship |

|---|---|---|

1.3D DRAWING 1.3D DRAWING 2.GRINDING MODEL 2.GRINDING MODEL 3.WAX INJECTION 3.WAX INJECTION 4.SEETTING STONES IN WAX 4.SEETTING STONES IN WAX 5.BUILD WAX TREE 5.BUILD WAX TREE 6.CASTING 6.CASTING 7.ROUGH POLISHING 7.ROUGH POLISHING 8.POLISHING 8.POLISHING 9.ULTRASONIC CLEANING JEWELRY 9.ULTRASONIC CLEANING JEWELRY 10.PLATING 10.PLATING 11.QUALITY CONTROL 11.QUALITY CONTROL 12.PACKING 12.PACKING | ||

Fully self-managed production process, ensuring efficient delivery

Strict Quality Control Standards

- • Raw Material InspectionEach batch of raw materials is strictly tested using an X-ray fluorescence spectrometer to ensure that the silver content reaches 930%, surpassing international standards, and thoroughly eliminating the presence of harmful allergens such as nickel and lead.

All materials are accompanied by authoritative test reports and support re-inspection and certification by third-party institutions.

- • Production Process MonitoringWe implement meticulous control through our fully self-managed production system, with a professional quality inspection team assigned to 12 key production stages from raw material entry to finished product shipment.

Through standardized procedures and real-time quality monitoring, we ensure that the defect rate in processes is strictly controlled within 0.1%, and the on-time delivery rate for orders is above 99.7%.

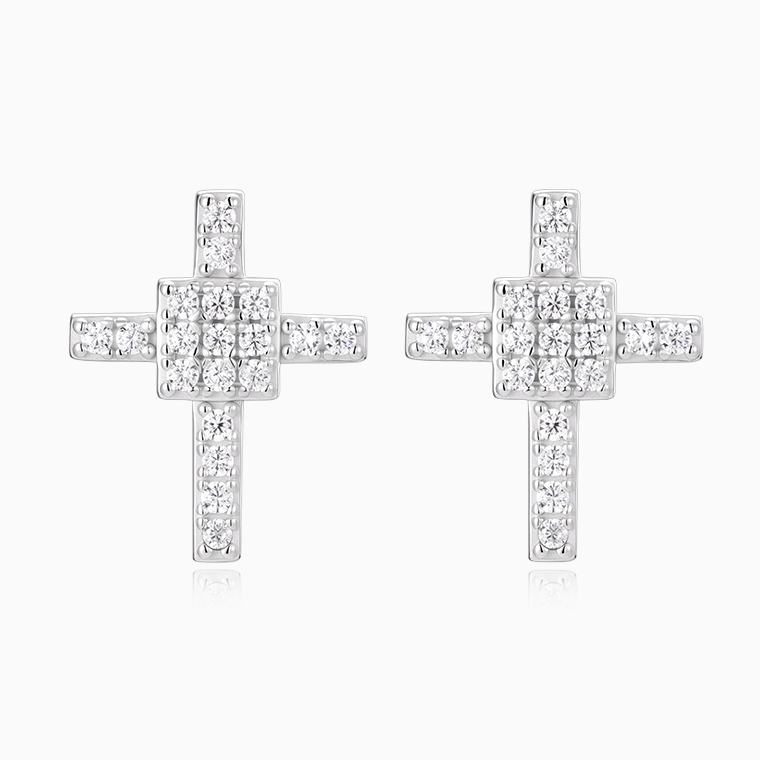

- • Finished Product InspectionJewelry finished product inspection strictly follows ISO 9001 quality management system standards.

Key indicators such as setting firmness, surface treatment, craftsmanship details, and tensile testing are performed on each product to ensure that every delivered item exceeds industry quality standards.

- • After-Sales SupportQuality Guarantee: 1-year warranty, comprehensive inspection, 24-hour response to quality issues.

Service Guarantee: Dedicated account manager and technical team for follow-up, offering 7×24-hour response support.

Global Sales | Trusted Manufacturing Factory

Built for Volume, Engineered for Excellence

- PendantMonthly output13KPCSProduction Line CapacityPrevious Year150KPCSActual Units Produced

- EarringMonthly output18KPCSProduction Line CapacityPrevious Year230KPCSActual Units Produced

- RingMonthly output12KPCSProduction Line CapacityPrevious Year130KPCSActual Units Produced

- NecklaceMonthly output20KPCSProduction Line CapacityPrevious Year240KPCSActual Units Produced

- BraceletsMonthly output10KPCSProduction Line CapacityPrevious Year110KPCSActual Units Produced

- Women's suitMonthly output10KPCSProduction Line CapacityPrevious Year130KPCSActual Units Produced

Fully self-managed production system, making quality more reliable!